This website provides an overview and a collection of informational resources regarding the increasingly important field of Systems and Software Product Line Engineering (PLE):

What is Product Line Engineering?

Virtually all systems engineering is performed in the context of a product line — a family of similar systems with variations in features and functions. Hardly anyone builds just one edition, just one flavor, just one point solution of anything. In contrast, systems engineering methods and tools have traditionally focused on how to build the individual point solutions within a family, rather than how to engineer a system family as a whole.

Organizations developing a line of similar products or systems frequently struggle with the complexity of digital engineering in combination with system family engineering. This complexity stems from non-digital approaches to engineering, such as spreadsheets, documents, clone-and-own, and tribal knowledge, resulting in low-value replicative work, miscommunication, and errors. Each of these introduces significant risks in the form of engineering complexity, defects, errors, and omissions leading to delays, budget overruns, recalls, system failures, and opportunity losses.

Feature-based Product Line Engineering

Product Line Engineering (PLE) mitigates risk by providing the models, tools, and methods for holistic system family engineering. Feature-based PLE is the modern digital engineering industry best practice for PLE, as defined in the INCOSE Product Line Engineering Primer, Feature-based Systems and Software Product Line Engineering: A Primer (INCOSE, 2019) and the ISO/IEC 26580 Feature-based PLE standard, Methods and tools for the feature-based approach to software and systems product line engineering (ISO/IEC 26580, 2021). Feature-based PLE offers significant improvements and benefits in effort, cost, time, scale, and quality by exploiting system similarity while providing formal variation/variant management.

Feature-based PLE is used to engineer a system family as a single production system rather than a multitude of individual systems. It consolidates engineering assets in each engineering discipline to eliminate duplication and divergence. It applies a single authoritative variation management model consistently across all assets in all engineering disciplines, eliminating that source of dissonance across the lifecycle and enabling organizations to make informed and deliberate cost-benefit decisions about the variations designed into their system family.

A note on terminology: Where the PLE field and standards refer to “product” and “product line”, the equivalent terms in systems engineering are “system” and “system family”. These terms can be used interchangeably.

Key Elements of a Feature-based PLE Factory

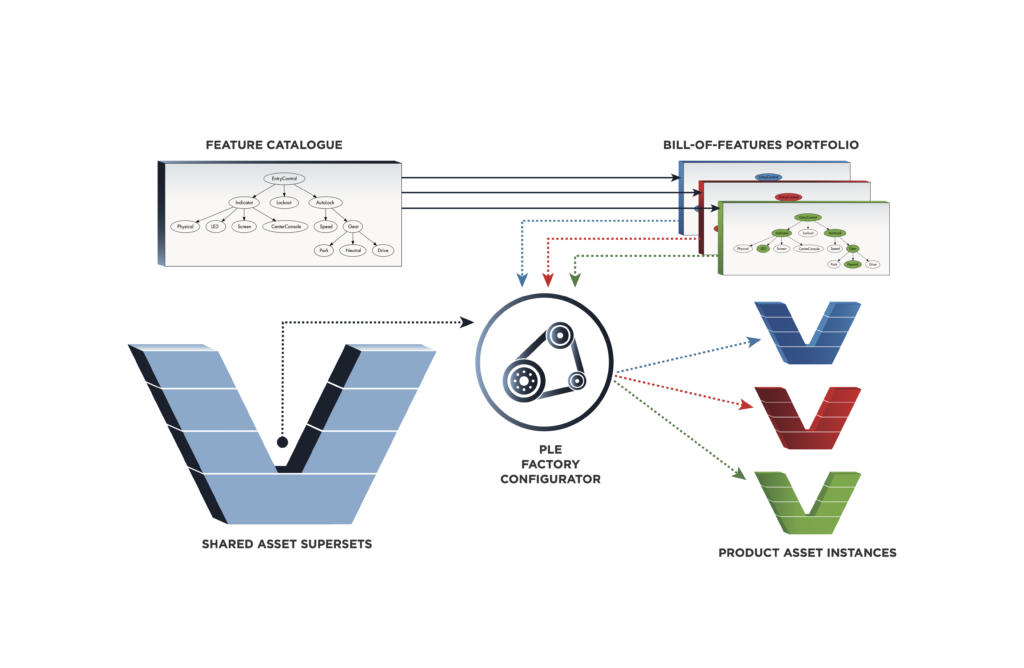

Feature-based PLE uses a PLE Factory metaphor (See ISO/IEC 26580 for a full description), and the following elements are integral to how such a factory works.

- Feature Catalogue captures a formal model of the distinguishing characteristics about how the members of the system family differ from each other. It provides a common language and single authoritative source of truth about variation throughout the engineering organization.

- Bill-of-Features specifies the features selected from the Feature Catalogue for each system in a system family portfolio.

- Shared Asset Supersets are the engineering artifacts that support the creation, design, implementation, deployment, and operation of systems in a system family. They contain variation points —pieces of content that can be included, omitted, generated, or transformed for a system instance — based on the features selected in a Bill-of-Features for that system.

- PLE Factory Configurator is automation that applies a Bill-of-Features for a system to each variation point in the Shared Asset Supersets to determine each variation point’s content for the system instance.

- Product Asset Instances each contain only the shared asset content suited for that one system in the system family

With Feature-based PLE, engineers now work on the Shared Asset Supersets, the Feature Catalogue, and the Bills-of-Features within the PLE Factory, rather than on the individual system instances. Once the PLE Factory is established, engineering assets for the individual systems are automatically instantiated rather than manually engineered. Feature-based PLE transforms the complex task of engineering a plethora of individual systems into the much-more-efficient task of producing a single system: The PLE Factory itself. This consolidation also means that change management and configuration management are performed on the single PLE Factory rather than separately on each of the system instances.

PLE yields a much higher degree of system family engineering efficiency than ever thought possible. Feature-based PLE takes advantage of the commonality shared among the family and efficiently and systematically manages the variation among the products and features. Through automation, this management delivers even greater improvements throughout some of the PLE yields a much higher degree of system family engineering efficiency than ever thought possible. Feature-based PLE takes advantage of the commonality shared among the family and efficiently and systematically manages the variation among the products and features. Through automation, this management delivers even greater improvements throughout some of the most challenging engineering industries. The resulting effort avoidance on mundane and manual tasks allows engineers to focus on high-value work that helps their companies better meet customer demands, increasing customer satisfaction and loyalty.

Download the INCOSE Product Line Engineering Primer and get the ISO 26580 standard on Feature-based PLE for a more comprehensive overview of Feature-based PLE.